Orlando Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is a well-known method that helped American companies overcome the Japanese market dominance in the 1980s when American industries were losing ground in terms of products and services. Because Sigma is beneficial for professionals and students, it has gained popularity beyond the simple fact of why it was created in the first place. It can be used in your everyday life to enhance your personal growth and help you achieve greater results. However, there is a lot involved in how LSS helps you achieve this and when determining if this is a methodology you want to invest time in. At Lean Six Sigma Curriculum for Orlando High School Students of Florida, our goal is to offer all the knowledge people, companies, and institutions need to learn about LSS.

If you don’t know where to start or what is the right step to take, we encourage you to read the history of LSS. It will show how it became a tool that not just enhances industries but also adds value to the lives and work of individuals.

Let’s begin by saying that Lean Six Sigma is a blend of Japanese management principles with original methodologies such as Six Sigma and Lean. These two methodologies can be traced back all the way to the United States, and they are crucial if you want to understand the entire scope of Sigma and how it came to be a crucial methodology.

The field of methodology has also been influenced by Kaizen. Because it stresses cooperation, commitment, and customer satisfaction, it is the one that helped Japanese companies to thrive in the 1980s. LSS incorporated several elements of it to help American companies achieve remarkable results.

This was not the only method that allowed for growth in the 1980s. In prior years and in the same decade, other methods were also developed.

LSS was influenced in other ways, but we don’t need to look at each one individually to understand their function and how they have progressed over time.

Instead, let’s focus on the history and significance of Six Sigma and Lean as the main methods.

Six Sigma and Lean: What Do We Know About Them

It is crucial to know the differences between these two methods. Most people mistakenly believe that it is another way to call LSS when, in fact, they are all completely different.

LSS can be partially considered a combination of the two, but it also adds more principles to the final formula. Each methodology is unique because each has its own principles and basic concepts.

Because of its structure, principles, and purpose, Lean is often viewed as a way for customers to be more satisfied while decreasing waste. When referring to Toyota, many people refer to Lean origins.

Toyota was part of the development of the Toyota Production System (or TPS). John Krafcik, a researcher at MIT, was involved in the creation of the system. He provided the most important information on Lean and how it could help processes.

He was looking for a name to describe the TPS system. He wrote down the differences between Toyota’s system and traditional production on a whiteboard and, at the time, concluded that Toyota’s system required less of everything in order to create value and that efficiency could be achieved in fewer stages.

This is how Lean was born. It has been focusing on reducing waste and improving businesses in all areas to help individuals get the most from their efforts, reduce costs and increase revenues.

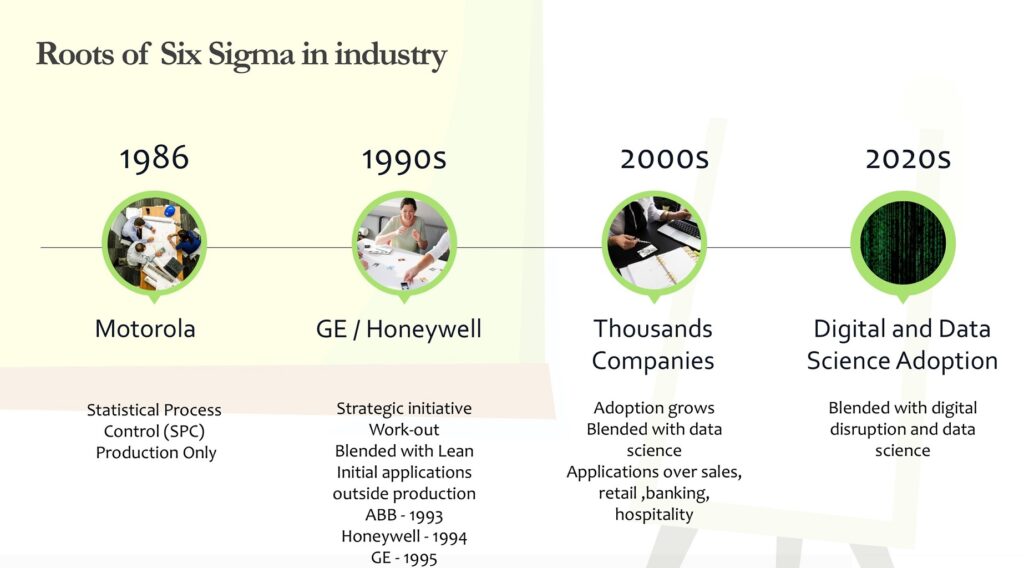

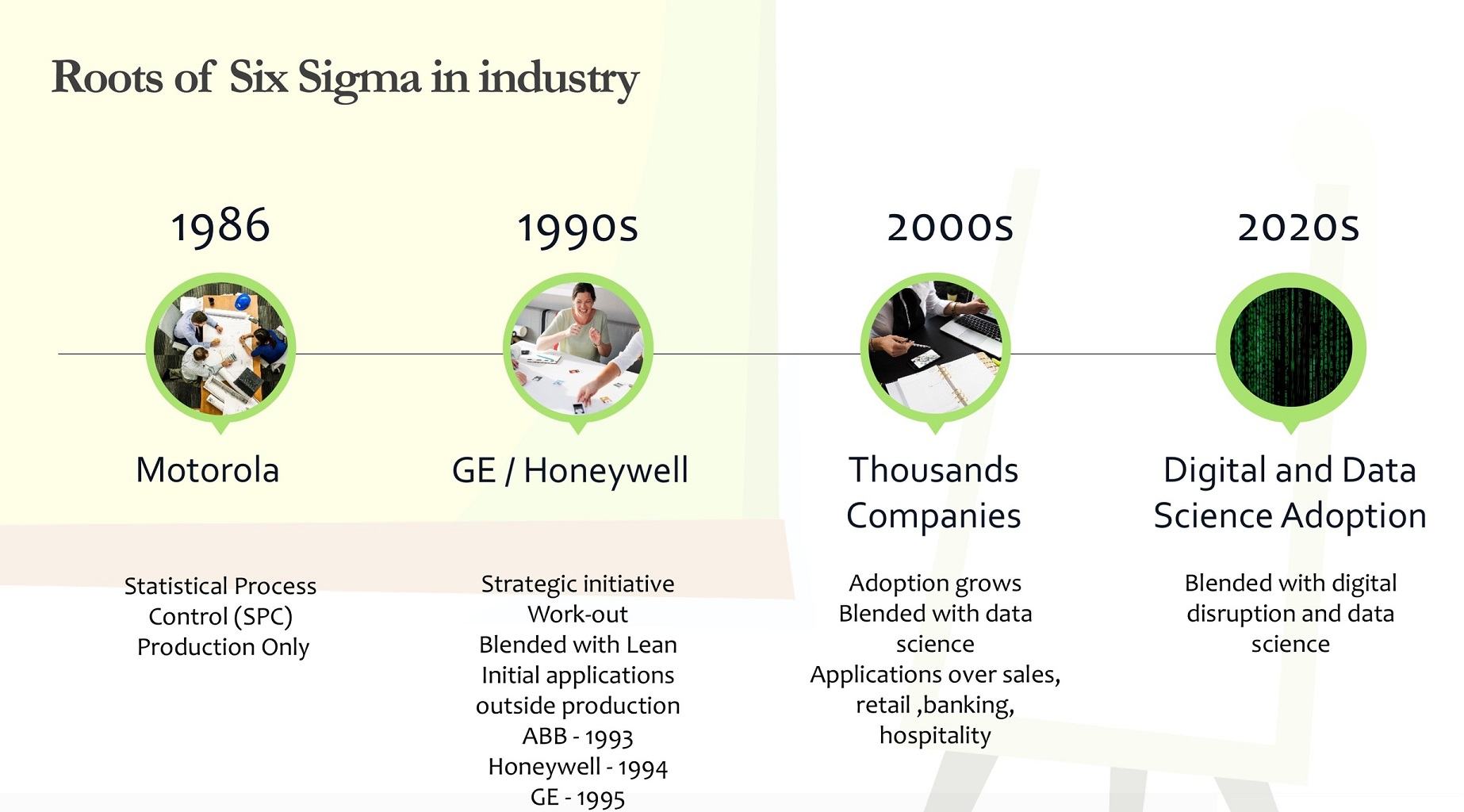

Six Sigma, an American-based methodology, dates back to the early 80s. Motorola created Six Sigma to solve problems it faced in dealing with foreign companies.

Motorola was able to achieve its goal of tenfold growth in five years thanks to this methodology, set by Bob Galvin (CEO).

This plan was aimed at global compatibility, improving participative management, quality and productivity, as well as how we can continuously develop new strategies. Motorola adopted Six Sigma quickly, and all employees were trained to use it.

Six Sigma and Lean both acknowledge the value and importance of change. They work well together to create LSS around their principles and add details.

What Does This Mean for Lean Six Sigma?

LSS has been used in many ways throughout history, but it first started in manufacturing for the reasons we have mentioned so far.

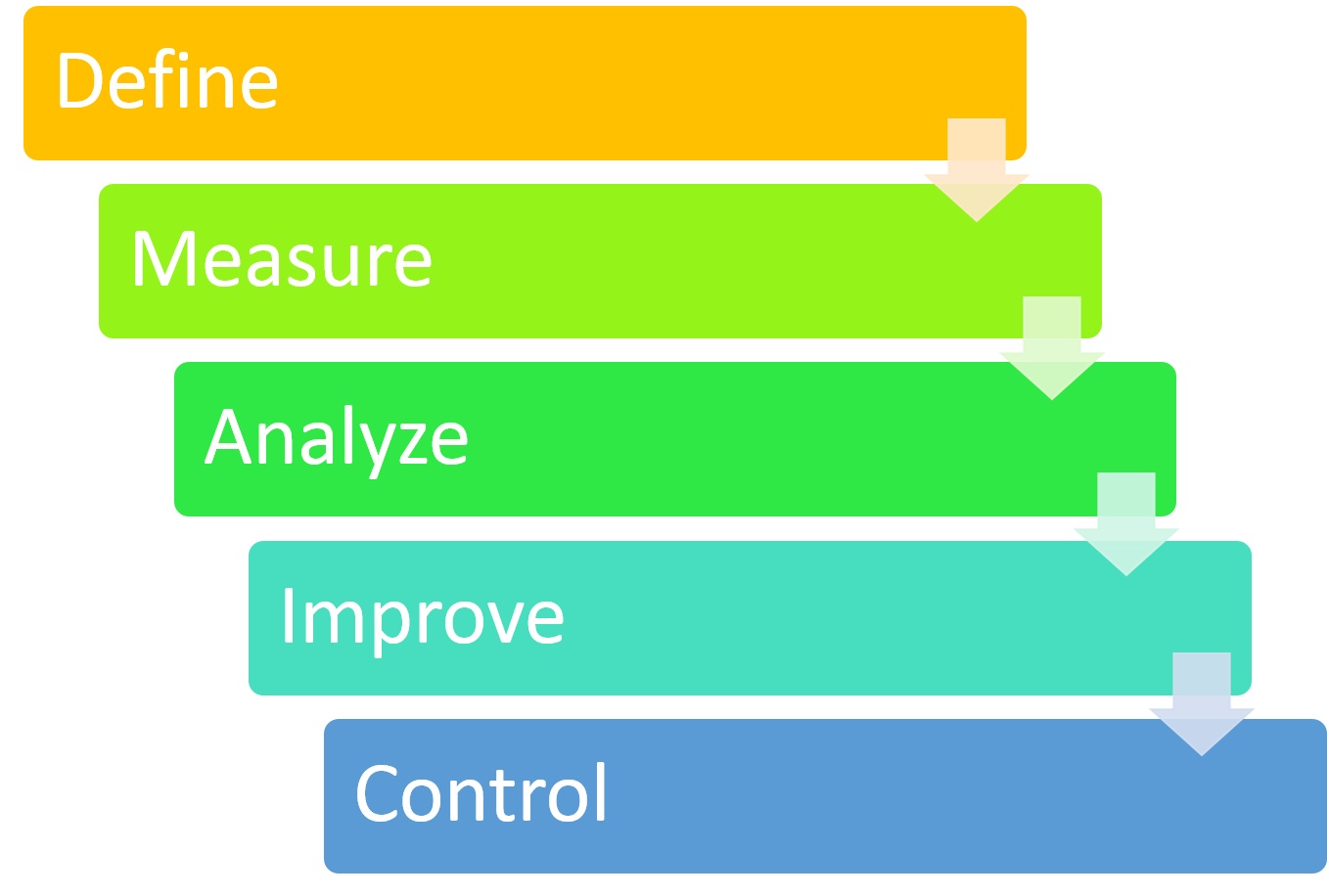

It can improve productivity and efficiency, reduce waste, and improve quality. Since it allows practitioners to focus on specific issues and projects, it is possible to utilize it in more than the regular processes.

Let’s examine the main benefits of LSS using these three methods to understand its growth in the 1980s.

Lean helps both employees and companies to better understand customers and prioritize customer needs. They can then focus on the core value stream of the company and its processes to achieve perfection.

Six Sigma is dedicated to excellence, and Kaizen ensures customer happiness more than any other.

Lean Six Sigma is a great tool for students, professionals, and individuals. It allows them to achieve the same results without needing to go through each step or having to apply all three methodologies individually. The common results to achieve are:

- Learn how to reduce waste.

- Increase efficiency.

- Reduce errors.

- The company will be less vulnerable.

- You can improve your time management.

- Lower costs equal higher revenues and better wages.

- Get motivated.

- Leadership and innovation.

Contact our Lean Six Sigma Curriculum Pros of Orland team for more information. Our experts can help your employees and students learn the methodology to be problem solvers, continuous improvement specialists, and team builders, and help them with many other skills.

We want you to feel valued and to be able to enjoy every aspect of your job. Even if you feel isolated, we are here to support you.